All Categories

Featured

Table of Contents

- – Rv Floor Replacement Placentia, CA

- – OCRV Center

- – Replacement Windows For Rv Placentia, CA

- – Rv Restoration Companies Placentia, CA

- – Rv Upholstery Placentia, CA

- – Rv Interior Remodel Placentia, CA

- – Rv Carpet Replacement Placentia, CA

- – Rv Sofas Placentia, CA

- – Rv Carpet Replacement Placentia, CA

- – Rv Sofa Beds Placentia, CA

- – Awnings For Rv Placentia, CA

- – Rv Couch Bed Placentia, CA

- – Rv Carpet Replacement Placentia, CA

- – OCRV Center

Rv Floor Replacement Placentia, CA

This aids jump sunshine away, more reducing heat inside your Motor home. Now, allow's address the condensation worry. Some RVers declare that double pane home windows minimize condensation, but below's the inside story: the window structure does not influence your RV's moisture.

To tackle it, you'll need a dehumidifier. Throughout the summertime, recreational vehicle air conditioning unit naturally evaporate. Nevertheless, in the wintertime, you lose this moisture-fighting result. If you're winter outdoor camping, take into consideration spending in a dehumidifier to keep condensation at bay. One indisputable benefit of dual pane home windows is their noise-canceling expertise. They do an exceptional work at minimizing outside noise, creating a much more serene space.

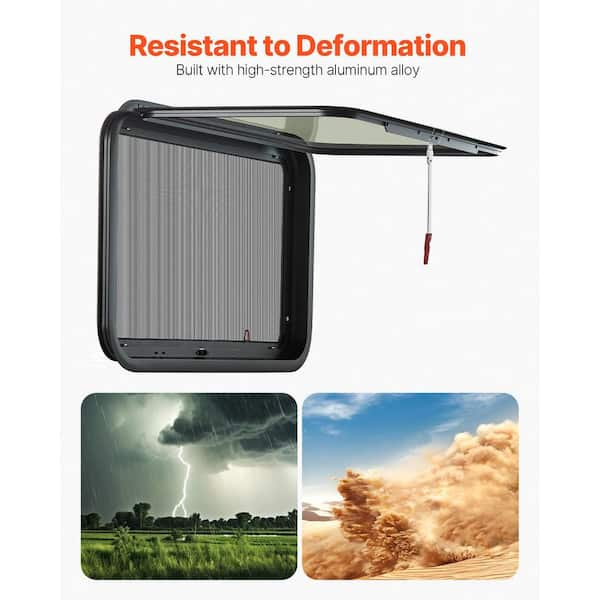

Currently, let's discuss Euro-style home windows. These are a rarity in the motor home globe, including a real twin pane with a hollow core in between. While it's challenging to select the specific R-value, individuals report they succeed at insulation and heat decrease. Keep an eye out for these on high-end Motor homes and truck campers.

While you're thinking about the Cinder brand, look into Josh's video clip and write-up where he showcases their finest features. If you find the excellent RV that lacks the thermal pane home window checkbox, do not worry. You can attain far better insulation with shades and reflective foil, all for a portion of the price of those costly window upgrades.

Replacement Windows For Rv Placentia, CA

Your recreational vehicle's home windows are the secret to satisfying outdoor camping, allowing you see all the views of the road and your locations. Placentia Remodeling Rv. If you're driving a motorhome, the windshield is one of the most vital window overall motor home. Despite which sort of motor home you possess, your windows are a fundamental part of camping

Older Motor homes were developed with much less advanced window systems, so there is wear and tear that may be obvious., but specific problems like fog, scrapes, or problems with the case of the window might mean it's time to replace your RV windows.

There are splits, deep scratches, or chips in the home windows. Wind or water goes into the rig from around the home windows, even when the home windows are closed. When replacing your Recreational vehicle windows, you're able to choose the right home window for your Motor home and your needs.

Rv Restoration Companies Placentia, CA

There are likewise options such as translucent glass, pebbled home windows, and tinted RV home windows. Your design, safety, and home window utilize needs will aid figure out which type of recreational vehicle home window you pick. Your recreational vehicle's window structures combine the interior and exterior elements of your recreational vehicle, and they should be appropriately installed to make certain that the sidewall's seal remains leak-proof.

The most effective way to see to it that your motor home home window replacements are installed effectively is to leave it to the experts. Our motor home service experts can change any kind of home windows and glass on your motor home, including the windscreen, side home windows, and also the much more complex recreational vehicle door home window substitute. Door windows, if not mounted correctly, can rattle when you're using the recreational vehicle door, so leave that repair to our professionals at Lazydays recreational vehicle.

One of the large things is the way they are made for rejecting water. The domestic home windows are made to be fixed.

Rv Upholstery Placentia, CA

Take that very same window and spray water at 60 miles an hour laterally and water will migrate in with the interlock bar, specifically leading and lower. The closing/ securing systems on a stick and blocks home window are not made for movement. Several have a decline lock or swivel catch just and it would walk around during traveling.

Residential windows are physically wider and would certainly not fit the wall surface thickness. Our normal Recreational vehicle wall surface is much less than half the thickness of the common 2X4 household wall surface.

Rv Interior Remodel Placentia, CA

These home windows open outward with a crank mechanism, enabling for air flow while minimizing rain entrance. Commonly larger windows that do not open, providing unblocked views and light if outfitted.

Bolts safeguarding the preserving ring. Gives a leak-proof seal around the home window. These components are installed on the assembly line shortly after the wall surface setting up, guaranteeing the structural stability of your motor home. While recreational vehicle home windows differ from domestic windows, they call for regular interest and maintenance to prevent concerns like water leakages.

See to it to look for room-by-room display removal as required. To guarantee the long life and efficiency of your recreational vehicle home windows, think about the following tips: Examine the location where the home window satisfies the wall surface for any voids or gaps. Tidy the area thoroughly prior to applying silicone sealant. In severe cases, you might require to remove the window and re-install it using putty or foam seal.

We encourage users to validate the components and consult with their dealer or Keystone RV for the most existing information. If you have any type of inquiries or require more clarification, please do not wait to call your supplier or connect to Keystone recreational vehicle directly.

Rv Carpet Replacement Placentia, CA

A recreational vehicle is part house and part car, and sometimes, after the "home" has been driven for miles and miles over bumpy roads, maintenance concerns can develop. Amongst the potential repair services that a recreational vehicle owner may deal with is a RV home window replacement. We encountered this problem several years back and satisfied it head-on with our need to DIO (Do It Ourselves) as most of our own recreational vehicle upkeep and repair projects as feasible.

These are the devices we needed for our camper home window replacement. Depending on your Motor home, you might or may not require all of these devices for your task.

Regardless of where you purchase your new motor home home window, you'll need to supply precise dimensions. Let's break down our procedure for measuring a recreational vehicle home window for replacement. Begin by removing any kind of window valance, blinds, or tones. Next, remove all screws around the border of the home window, and get rid of the inside structure.

Rv Sofas Placentia, CA

Don't place any external stress on the home window while taking your dimensions or it can come loosened and fall. For extra security, you may wish to have an assistant on a ladder outside, holding the home window in place while you measure. Carefully get rid of the structure of your old home window so that you can determine the opening (NOT the home window itself).

For our rectangle-shaped home window, we required to take just 4 measurements. It's a great concept to take dimensions at several points so you have an idea of how cleanly the home window opening was reduced.

Next off, gauge the thickness of the wall (depth of the home window), from the exterior wall surface area to the indoor wall surface. For this dimension, use your leader (with dimensions that run completely throughout). Put the leader right into the wall until it touches the beyond the home window structure.

Rv Carpet Replacement Placentia, CA

Dimensions of the old window and the window opening are usually various. In reality, they can differ as much as half an inch on the sides, leading, and base. Window makers use filler strips to maintain the window level and snug. This is why it's so essential to gauge the opening and not the initial home window itself.

Take your time to obtain an accurate dimension, and confirm it by measuring a 2nd time. Precise measurements are vital to Motor home window replacement. Take a close appearance at your tape action and be certain you know which are the 1/16th-inch measurements.

Rv Sofa Beds Placentia, CA

The window manufacturers are the best authorities on mounting their items. The maker of your brand-new recreational vehicle home window has likely included handy standards or tips to make the installment easier. These kinds of directions are commonly consisted of on manufacturers' web sites. If your new window included instructions in the bundle, make certain to keep those helpful as they may have described step-by-step instructions in an included brochure.

Make certain the home window is OPEN to ensure that you can securely grasp the home window as it drops out of the opening, when the seal is broken. Remove any type of staying sealer utilizing your plastic putty blade, and wipe any type of continuing to be debris utilizing mineral spirits. Provide the area a final cleansing utilizing massaging alcohol to guarantee that the area around the window opening is without any kind of oily deposit.

Awnings For Rv Placentia, CA

Begin by setting your new home window on a level surface area covered with a soft cloth, with the exterior of the window facing down. Using the included roll of double-sided, closed-cell foam tape, apply the tape.

Remove the paper backing of the tape simply before rounding each edge for an excellent, level, unbroken seal. When you reach completion, reduced the tape to enable regarding inch of the end of the tape to overlap the factor where you began. Once you have actually brought the foam tape around to meet the beginning, overlap the end of the tape concerning 1/2 inch, ensuring an excellent seal.

It may seem odd to damp something you desire to stick, however it will aid you to put the window WITHOUT it adhering to the recreational vehicle sidewall. When the water vaporizes, it will certainly permit the structure of the window to stick to the external wall surface of the recreational vehicle, giving a water-tight seal.

Establish the brand-new home window right into the opening gently don't press the tape right into area simply. Placentia Remodeling Rv. Once the home window is positioned appropriately, press against the home window structure from the outside, strongly adhering the foam tape to the Recreational vehicle.

Rv Couch Bed Placentia, CA

See our video on top of this message for specific instructions on the very best procedure for screwing in the new window structure correctly. Wipe off any excess water, press both drain covers right into location at the end of the frame, and stand out the screen into its track. If your RV's manufacturer made use of sealant on top of your home windows as Newmar finished with ours, we suggest replacing that sealer currently utilizing the Pro-Flex motor home Sealant.

Make sure the window is OPEN to make sure that you can firmly understand the window as it befalls of the opening, as soon as the seal is damaged. Remove any remaining sealer utilizing your plastic putty knife, and cleanse off any type of continuing to be debris using mineral spirits. Provide the location a final cleaning utilizing rubbing alcohol to guarantee that the area around the home window opening is complimentary of any oily deposit.

Begin by setting your brand-new window on a flat surface area covered with a soft cloth, with the outside of the home window facing down. Using the consisted of roll of double-sided, closed-cell foam tape, use the tape.

Get rid of the paper backing of the tape simply before rounding each edge for a best, level, unbroken seal. When you reach the end, reduced the tape to permit about inch of the end of the tape to overlap the point where you started. Once you've brought the foam tape around to fulfill the start, overlap the end of the tape regarding 1/2 inch, guaranteeing a good seal.

Rv Carpet Replacement Placentia, CA

It may appear strange to wet something you wish to stick, but it will certainly assist you to put the home window WITHOUT it adhering to the motor home sidewall. Placentia Remodeling Rv. As soon as the water vaporizes, it will certainly permit the frame of the window to stick to the outer wall surface of the recreational vehicle, offering a water-tight seal

Set the new window into the opening gently do not push the tape right into location just. Once the home window is located appropriately, press versus the window frame from the outdoors, securely adhering the foam tape to the Recreational vehicle.

OCRV Center

Address: 23281 La Palma Ave Yorba Linda, CA 92887Phone: (714) 909-1444

Email: [email protected]

OCRV Center

See our video on top of this message for explicit directions on the very best procedure for screwing in the new home window structure properly. Rub out any type of excess water, press the 2 drainpipe covers right into place at the base of the frame, and pop the screen into its track. If your RV's maker used sealer on top of your home windows as Newmar finished with ours, we recommend replacing that sealant at this time utilizing the Pro-Flex recreational vehicle Sealant.

Replacement Rv Windows Placentia, CAReplacement Rv Windows Placentia, CA

Rv Interior Remodel Placentia, CA

Rv Couch Bed Placentia, CA

Awnings For Trailers Placentia, CA

Awning Installation Placentia, CA

Rv Replacement Furniture Placentia, CA

Rv Microwave Replacement Placentia, CA

Rv Replacement Furniture Placentia, CA

Rv Couch Placentia, CA

Motorhome Carpets Placentia, CA

Rv Carpet Installation Placentia, CA

Replacement Windows For Campers Placentia, CA

Rv Interior Remodel Placentia, CA

Awnings For Trailers Placentia, CA

Rv Refrigerator Replacement Placentia, CA

Replace Rv Flooring Placentia, CA

Rv Dinette Booth Placentia, CA

Awning Installation Placentia, CA

Rv Replacement Awnings Placentia, CA

Rv Sofa Sleeper Placentia, CA

Awnings For Rv Placentia, CA

Rv Sofa Sleeper Placentia, CA

Replacement Windows For Campers Placentia, CA

Rv Carpet Installation Placentia, CA

Rv Refrigerator Replacement Placentia, CA

Awnings For Trailers Placentia, CA

Rv Replacement Awnings Placentia, CA

Rv Sofa Beds Placentia, CA

Rv Replacement Awnings Placentia, CA

Rv Sofa Beds Placentia, CA

Awnings For Trailers Placentia, CA

Rv Dinette Booth Placentia, CA

Awning Installation Placentia, CA

Replacement Windows For Rv Placentia, CA

Replace Rv Flooring Placentia, CA

Rv Restoration Companies Placentia, CA

Rv Interior Furniture Placentia, CA

Awnings For Trailers Placentia, CA

Rv Dinette Table Placentia, CA

Rv Interior Remodel Placentia, CA

Rv Floor Replacement Placentia, CA

Awning Installation Placentia, CA

Rv Replacement Furniture Placentia, CA

Replacement Rv Refrigerator Placentia, CA

Rv Replacement Furniture Placentia, CA

Remodeling Rv Placentia, CA

Rv Dinette Booth Placentia, CA

Rv Couch Bed Placentia, CA

Motorhome Carpets Placentia, CA

Awnings For Rv Placentia, CA

Rv Couch Bed Placentia, CA

Rv Sofas Placentia, CA

Motorhome Carpets Placentia, CA

Rv Microwave Replacement Placentia, CA

Rv Interior Remodel Placentia, CA

Awnings For Trailers Placentia, CA

Replace Rv Flooring Placentia, CA

Rv Microwave Replacement Placentia, CA

Rv Interior Furniture Placentia, CA

Rv Replacement Furniture Placentia, CA

Rv Couch Placentia, CA

Rv Dining Table Placentia, CA

Awnings For Trailers Placentia, CA

Rv Replacement Awnings Placentia, CA

Rv Sofa Sleeper Placentia, CA

Motorhome Carpets Placentia, CA

Rv Dining Table Placentia, CA

Replacement Windows For Campers Placentia, CA

Rv Couch Placentia, CA

Rv Couch Placentia, CA

Rv Dinette Booth Placentia, CA

Rv Chairs Placentia, CA

Rv Dinette Booth Placentia, CA

Rv Dining Table Placentia, CA

Rv Carpet Installation Placentia, CA

Rv Replacement Furniture Placentia, CA

Rv Carpet Installation Placentia, CA

In My Area Seo Service Placentia, CA

In My Area Seo Company Near Me Placentia, CA

OCRV Center

Table of Contents

- – Rv Floor Replacement Placentia, CA

- – OCRV Center

- – Replacement Windows For Rv Placentia, CA

- – Rv Restoration Companies Placentia, CA

- – Rv Upholstery Placentia, CA

- – Rv Interior Remodel Placentia, CA

- – Rv Carpet Replacement Placentia, CA

- – Rv Sofas Placentia, CA

- – Rv Carpet Replacement Placentia, CA

- – Rv Sofa Beds Placentia, CA

- – Awnings For Rv Placentia, CA

- – Rv Couch Bed Placentia, CA

- – Rv Carpet Replacement Placentia, CA

- – OCRV Center

Latest Posts

Concrete Patio Contractor Near Me Hayward

Moraga Concrete Patio Contractor Near Me

Walnut Creek Remodeling Bathroom

More

Latest Posts

Concrete Patio Contractor Near Me Hayward

Moraga Concrete Patio Contractor Near Me

Walnut Creek Remodeling Bathroom